A research team from the National Institute for Materials Science (NIMS) has pioneered an automated high-throughput system designed to generate extensive datasets from a single sample of a superalloy used in aircraft engines. This innovative system produced an experimental dataset comprising thousands of records in just 13 days, a process that would typically take conventional methods over seven years to complete.

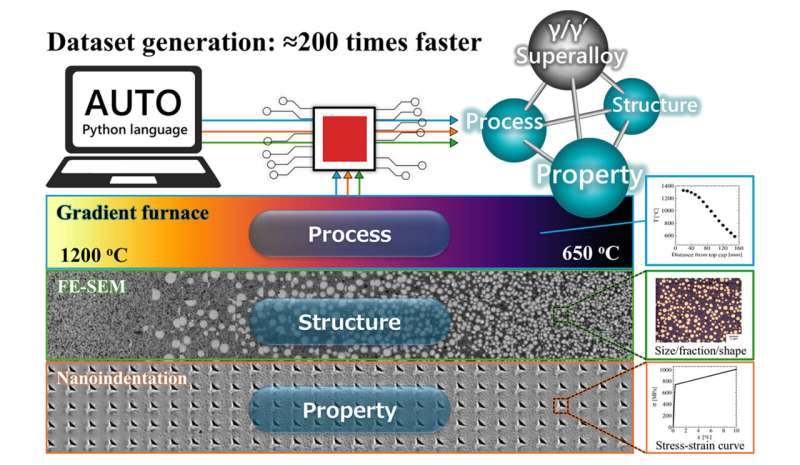

The newly developed automated system is capable of producing Process–Structure–Property datasets, which detail interconnected processing conditions, microstructural features, and resulting yield strengths. This capability significantly enhances the speed at which researchers can gather crucial data necessary for advancing materials science, particularly in the development of high-performance superalloys.

Transforming Materials Research

The significance of high-precision experimental data cannot be overstated in the fields of material science and engineering. Such data is essential for understanding material mechanisms, developing theoretical frameworks, constructing models, and conducting numerical simulations. These datasets are particularly vital for optimizing the processing methods of heat-resistant superalloys, which are critical for applications in aerospace and other high-stress environments.

Typically, assembling comprehensive databases requires extensive time and financial resources. The NIMS team has addressed this issue with their new system, which can generate thousands of data points from a single sample of a Ni-Co-based superalloy. This specific superalloy was developed by NIMS for use in turbine disks of aircraft engines, underscoring its relevance in the industry.

The automated evaluation system utilizes a gradient temperature furnace to thermally treat the superalloy sample, effectively mapping a wide range of processing temperatures. Following this, measurements of precipitates and yield stress were conducted at various coordinates along the temperature gradient. This process was facilitated by a scanning electron microscope controlled by a Python API and a nanoindenter, allowing for rapid data collection and processing.

Future Applications and Goals

The implications of this research extend beyond the immediate results. The NIMS team plans to leverage this automated system to construct databases for various target superalloys and develop new technologies for acquiring high-temperature yield stress and creep data. Additionally, they aim to formulate multi-component phase diagrams, which are essential for effective materials design.

Through these efforts, the research team intends to explore new superalloys with desirable properties, employing data-driven techniques to achieve their goals. A significant aspiration of this work is to fabricate new heat-resistant superalloys that could contribute to achieving carbon neutrality in the aerospace sector and beyond.

The findings of this research are documented in the journal Materials & Design, highlighting the system’s potential to revolutionize the way materials scientists approach the study and development of advanced materials.

For further details, see the publication by Thomas Hoefler et al in Materials & Design, dated November 11, 2025.