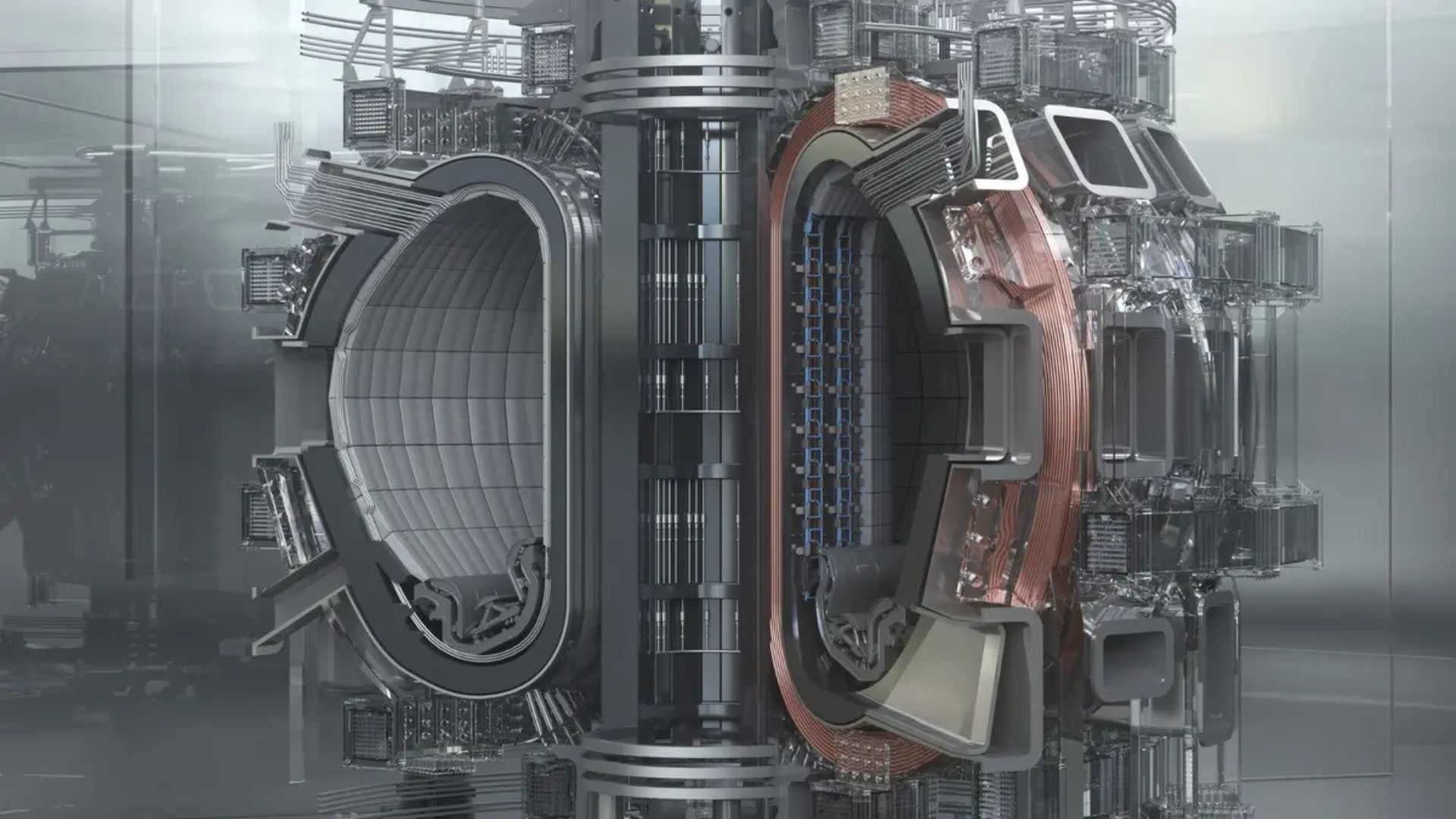

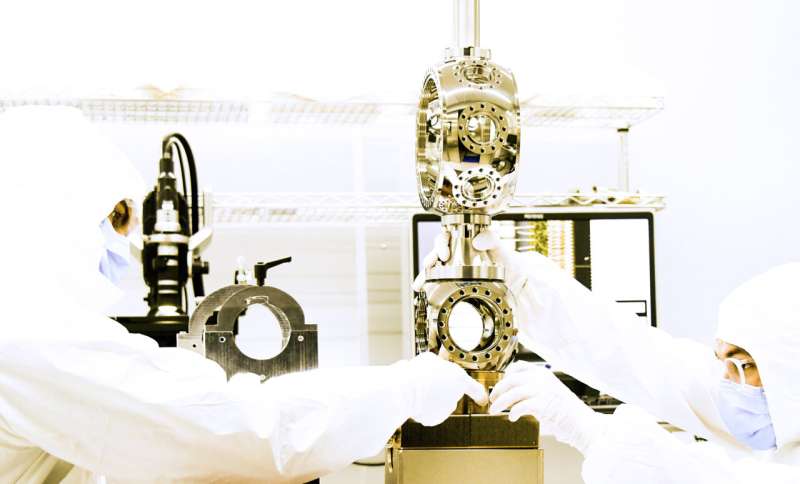

China has made a significant advancement in its nuclear fusion program, known as the “artificial sun,” by developing a critical component that was previously imported. Researchers from the Institute of Metal Research under the Chinese Academy of Sciences announced on Tuesday that they successfully created a domestic purification technology for Hastelloy (C276) metallic substrates. This innovation is essential for constructing the powerful “super magnets” required for nuclear fusion devices.

Professor Rong Lijian, who led the research, described this development as a solution to a major strategic bottleneck in China’s superconducting materials sector. Historically, while China has excelled in superconducting technologies, it has depended on expensive and uncertain imports for the C276 substrates. This breakthrough allows for a reliable, domestically-sourced material for the Burning Plasma Experimental Superconducting Tokamak (BEST), which is currently under construction in Hefei.

Mao Ning, spokesperson for China’s Foreign Ministry, stated that the BEST is scheduled for completion in 2027 and aims to be the first in history to generate electricity from fusion. This ambitious project underscores China’s commitment to leading in the field of nuclear energy.

Technical Innovations and Implications

Controlled nuclear fusion devices require confinement of plasma at temperatures exceeding 100 million degrees Celsius. Achieving this feat necessitates the generation of immensely powerful magnetic fields, which are produced using second-generation high-temperature superconducting tapes. The C276 substrate serves as the foundational element for these tapes, providing both mechanical strength and stability to the superconducting structure.

“Our team has accumulated nearly 20 years of experience in developing high-purity materials,” said Professor Rong. He highlighted that it took them less than two years to overcome specific processing challenges associated with this substrate.

The newly developed alloy is characterized as “ultra-pure,” with impurity levels for elements such as carbon, oxygen, and sulfur significantly lower than those found in similar imported materials. Researchers successfully produced a metallic strip over 2,000 meters long and only 0.046 millimeters thick, achieving a mirror-like surface roughness of less than 20 nanometers. When cooled with liquid nitrogen, this material demonstrates a tensile strength exceeding 1,900 MPa. To put this into perspective, a fingernail-sized piece of the alloy could support the weight of 190 tons.

The alloy also exhibits exceptional thermal stability, retaining its strength even after exposure to temperatures as high as 900°C (approximately 1,652°F).

Construction Progress and Future Goals

Earlier this year, the BEST project entered a new construction phase focused on the assembly of its main machine. The successful installation of the Dewar base marks a significant milestone, as this component is crucial for maintaining the cryogenic temperatures necessary for the operation of the device’s powerful superconducting magnets. The Dewar functions as a large, vacuum-insulated vessel, which is vital for the project’s success.

The BEST is one of several major international fusion projects and aims to be the first to demonstrate practical electricity generation from fusion. Achieving this goal could potentially revolutionize energy production and contribute significantly to global efforts in sustainable energy solutions.

This recent development in China not only highlights the nation’s growing capabilities in high-technology materials but also positions it as a formidable player in the race for sustainable nuclear fusion energy.