A recent innovation in tool coating promises to enhance manufacturing processes across various sectors, including aerospace, automotive, and medical devices. Researchers have developed a new bi-layer AlTiN (aluminum titanium nitride) coating that significantly improves the performance and longevity of cutting tools used in high-speed machining of challenging materials such as stainless steel 304 (SS304). This breakthrough was reported on November 5, 2025, by Qianxi He in an article published by The Conversation.

Understanding the Challenges in Machining

Manufacturing industries rely heavily on materials that resist corrosion and have low thermal conductivity. These characteristics are crucial for components in airplanes, cars, and medical devices. Common materials like austenitic stainless steels, titanium alloys, and Inconel super-alloys are essential; however, they pose significant challenges during machining. The high-speed machining processes that shape these materials often lead to rapid tool wear, decreasing the lifespan of cutting tools.

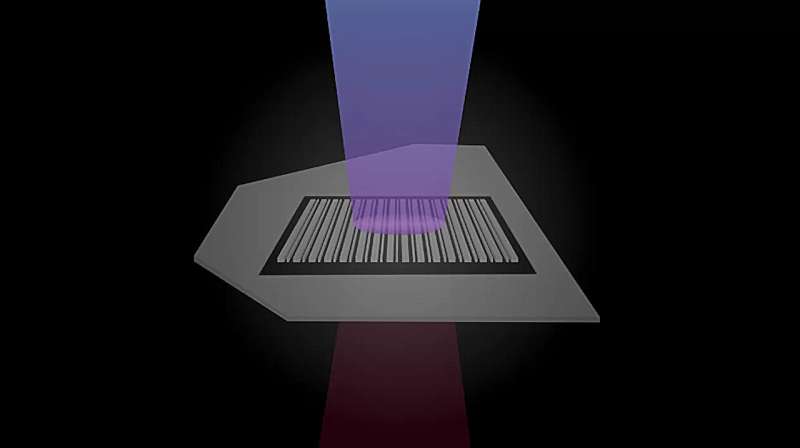

Machining involves selectively removing material from a workpiece to achieve specific shapes and dimensions. Traditionally, cutting tools are coated with a single layer of AlTiN to improve their wear resistance. While effective, these coatings struggle to balance the essential properties of hardness, toughness, and frictional performance required in demanding machining environments.

Introducing the Bi-Layer AlTiN Coating

The newly developed bi-layer AlTiN coating addresses these limitations by optimizing the mechanical properties of each layer. This innovative coating comprises two distinct AlTiN layers, each with varying ratios of aluminum and titanium. The top layer, featuring a higher aluminum content, reduces friction and enhances oxidation resistance. Meanwhile, the sub-layer, with an equal ratio of aluminum and titanium, improves hardness and adheres better to the tungsten carbide substrate used in cutting tools.

In extensive testing, this bi-layer coating demonstrated a 33% increase in tool life compared to traditional single-layer coatings. This notable improvement is attributed to its resistance to both crater wear, caused by extreme heat, and flank wear, resulting from mechanical stress.

The study specifically examined the bi-layer coating’s performance during ultra-high-speed turning of SS304, a widely used material known for its strength, corrosion resistance, and smooth surface finish. Applications for SS304 span automotive exhaust systems, aerospace components, food-processing equipment, and medical instruments.

The findings reveal that the bi-layer coating not only extends tool life but also enhances machining efficiency by producing smoother and more uniformly shaped chips during the cutting process. These chips indicate better frictional conditions, which in turn lessens resistance on the cutting tool, allowing for a more energy-efficient operation.

This innovation has the potential to significantly impact manufacturing processes by reducing energy consumption and costs associated with tool replacement and downtime.

As industries continue to strive for improved precision and efficiency, the development of advanced cutting tool coatings represents a critical advancement in material science and mechanical engineering. The ongoing research underscores the potential for such innovations to transform manufacturing practices in aerospace, automotive, energy, and medical device sectors, where performance and durability remain paramount.

The insights from this research highlight the exciting possibilities of advanced coatings in machining and manufacturing technologies, reinforcing the importance of continuous innovation in driving progress across various industries.